WinCast® expert is the world’s first casting simulation software on the market since 1984, developed by RWP GmbH, Germany. With virtual simulation the software supports you in planning and optimization for several types of process, e.g. sand casting, die casting, investment casting, high pressure die casting, low pressure casting, centrifugal casting, continuous casting, welding, heat treatment and many other special processes.

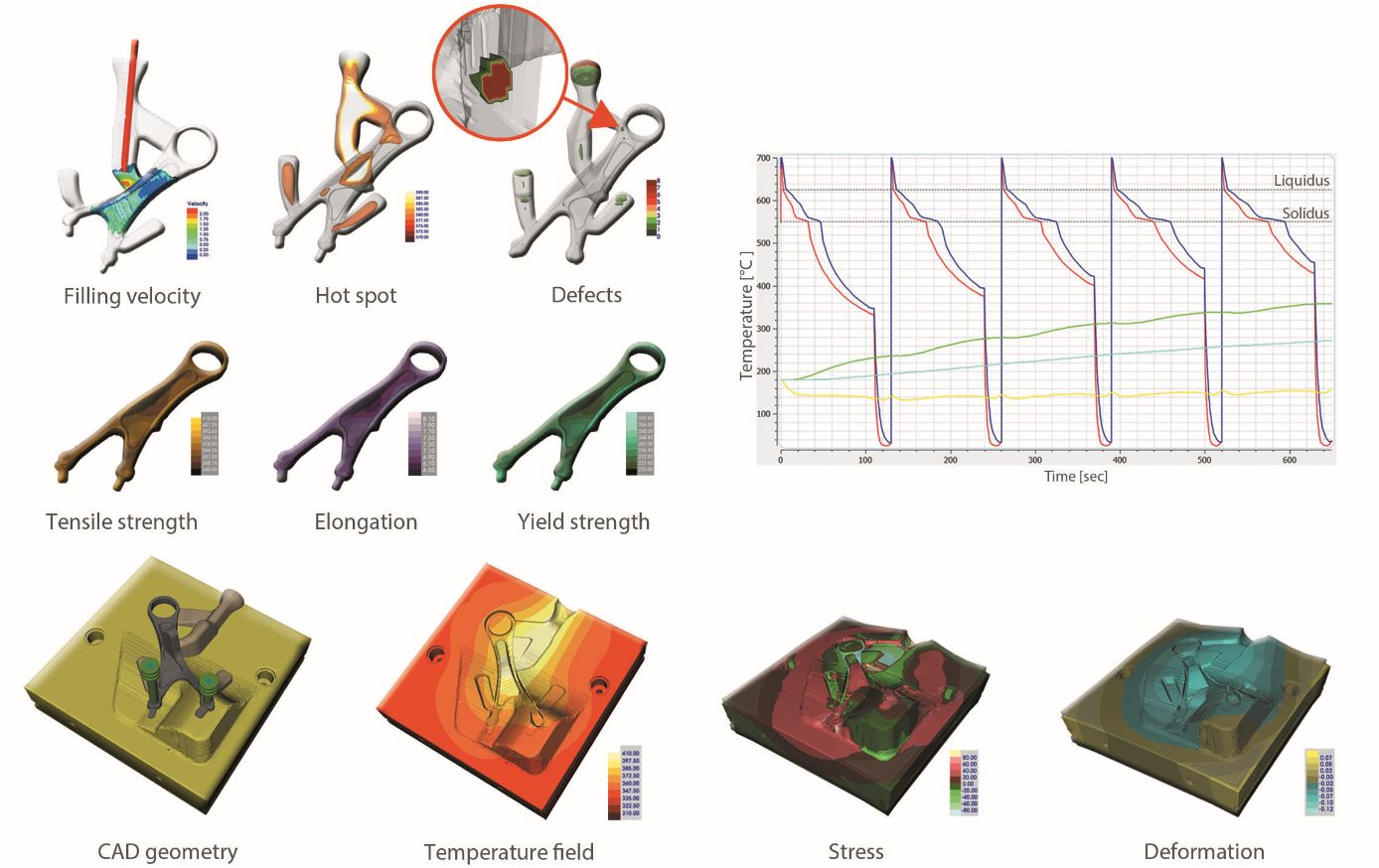

WinCast® expert calculates important quality requirements such as mold filling, solidification, porosity, residual stress, mechanical properties, deformation, hot cracking, hardness and service life and visualizes them to validate your process design prior to production.