RWP ANALYTICS®

RWP ANALYTICS® is the intelligent process monitoring and analysis system for foundries and manufacturing companies, developed by RWP GmbH, Germany. The system visualizes your process data in more meaningful way and brings added value. The goals of the system are to increase process transparency, stabilize the process and reduce rejects, and reduce raw material consumption and energy use.

What can RWP ANALYTICS® do?

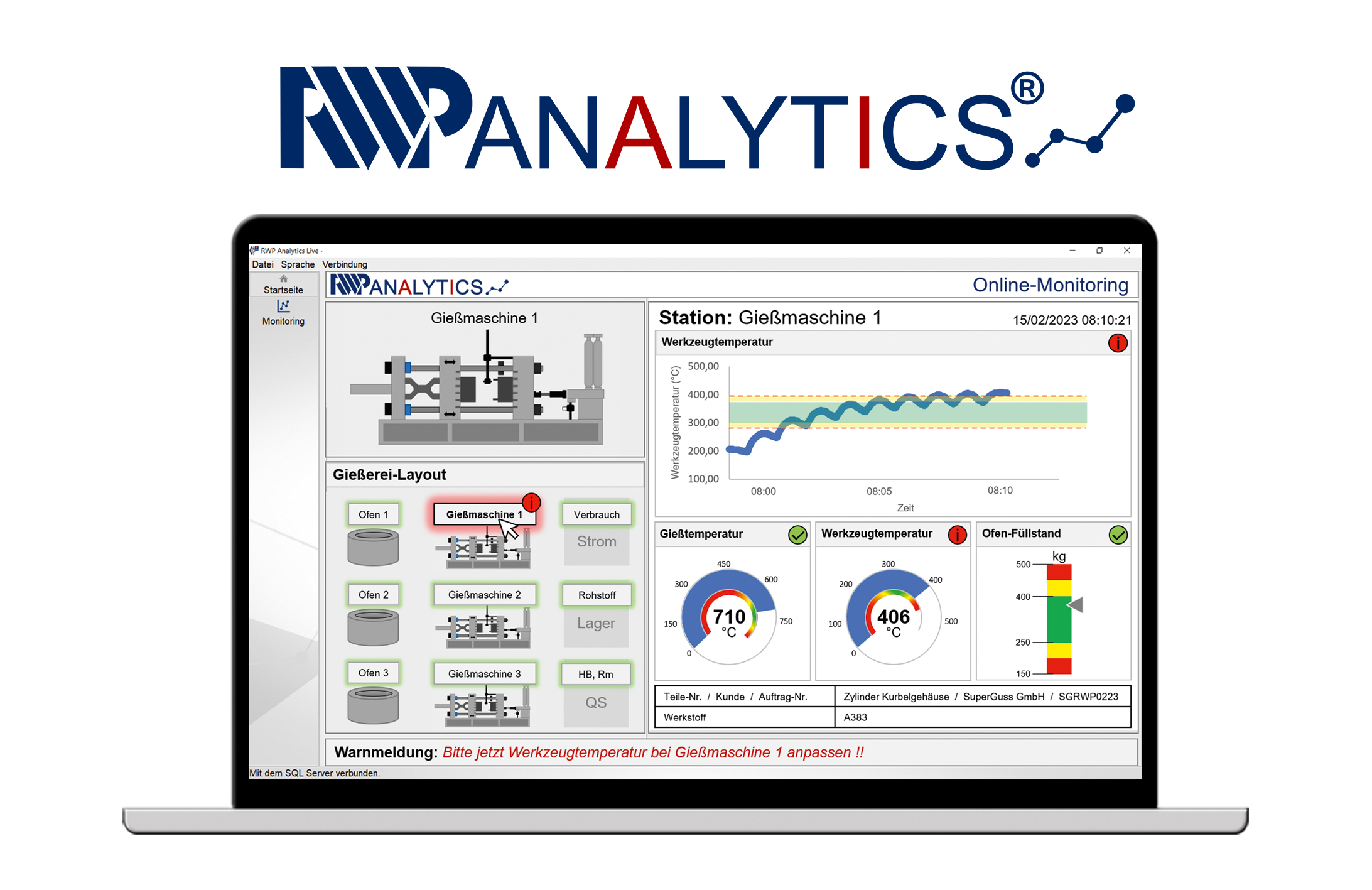

1) Online monitoring

Monitor the process parameters of all departments in your foundry. Receive a warning message directly at your workplace when action is required.

2) Data analysis

Determine possible causes of rejects and critical parameters by evaluating the data you have collected at the touch of a button.

Your benefits

- Faster and more accurate identification of problem areas in production

- Help with decision making

- Timely process correction

- More stable process

- Less waste, raw material and energy use